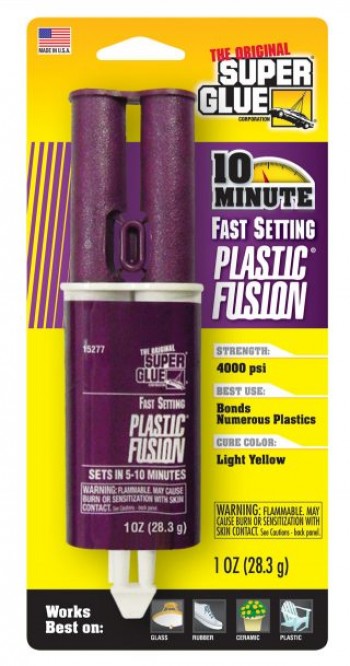

PLASTIC FUSION EPOXY

This acrylic-based, industrial-strength product dispenses resin and hardener automatically into equal parts with one push. Hold surfaces together with clamp, tape or weights. Allow 5-10 minutes for set time. 4000 psi strength bonds numerous plastics and works well for repairing plastic toys, fixtures made of plastic, metal, concrete and many other materials. Cures to an opaque light yellow color.

Directions:

(Note: not recommended for polyethylene or polypropylene bonding).

1.Surfaces should be clean and dry, free from oil and grease.

2.Roughen surfaces with emery cloth or sandpaper & wipe clean with solvent for best results.

3.Dispense from syringe and mix thoroughly, approximately 1 minute.

4.Apply to both surfaces and mate parts together.

5.Remove excess glue immediately with denatured alcohol.

6.Sets in 5-10 minutes at room temperature (77°F or 25°C) with full cure in 24 hours.

Works Best On:

- Ceramic

- China

- Concrete

- Glass

- Metal

- Most Plastics

- Rubber

Technical Specifications:

Initial color: Light yellow to amber

Final color: Light yellow

Positioning Time: 3 – 5 minutes

Set Time: 5-10 minutes @ 65-80°F

Handling Time: 2 hours

Full Strength: 24 hours

Maximum Gap: .25″

Shear Strength, Steel: 4000 psi (20%); Aluminum: 3500 psi (20%)

Operating Temperature Range: -40°F to 250°F (-40°C to 121°C)