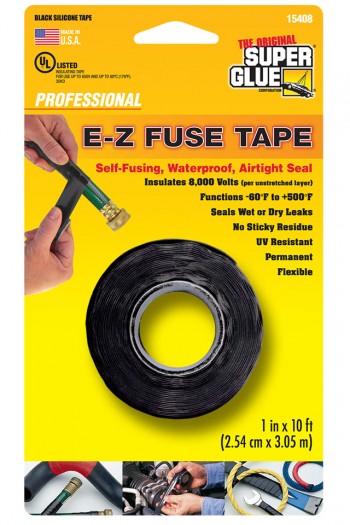

E-Z FUSE TAPE

E-Z Fuse Tape is a versatile, easy-to-use product. Designed to adhere to itself, this product leaves NO residue when removed. The bond is permanent, waterproof, airtight, non-conductive, insulating, and resists weathering, salt water, and UV rays. It seals wet or dry leaks, insulates 8,000 volts (per unstretched layer) and functions at -60° F to +500°F. The flexible material stretches around uneven shapes and is UL Listed. Use for: automotive, marine, electrical, plumbing, sealing, insulating and general purpose applications.

Directions:

1. Cut desired length of tape and remove the plastic protective film before using.

2. Hold E-Z Fuse Tape in position and apply a complete wrap back onto itself. This initial wrap secures the tape for additional wraps.

3. Maintain a constant stretch as you continue to wrap, making sure each new layer “half laps”onto the previous layer. These overlaps will fuse together.

4. Be certain the end of the final wrap is pressed down onto prior wraps. Use less stretch on the final wrap. If applying multiple pieces of tape, always start the end of each new piece in contact with a prior wrap.

5. For pressure applications, stretch E-Z Fuse Tape to the maximum and apply several tight layers. Non-pressure applications require only a minor stretch and one layer.

E-Z Fuse Tape layers begin to fuse immediately, forming a permanent, cohesive bond within 24 hours. Repositioning not recommended after 2 minutes of wrapping. E-Z Fuse Tape can be applied in wet, non-oily conditions, although dry surface conditions are suggested for best performance. Do not use on gas pipe or connections.

Works Best On:

Boat Rigging

Bundling Wires

Emergency O-Rings

Emergency Radiator Hose Repair

Plumbing Repair

Rope Ends

Weatherproofing Electrical Conn

Technical Specifications:

Operating temperature – continuous -49 to 392°F (-45 to 200°C)

Operating temperature – intermittent -85 to 500°F (-65 to 260°C)

Cold Brittle Point -85°F (-45°C)

Elongation, minimum (ASTM D119) 300%

Dielectric Strength, Minimum (MIL-I-46852) 400 V/mil

Tear Strength, Minimum (ASTM D264) 85 ppi

Tensile Strength, Minimum (ASTM D119) 700 psi